5 Reasons to Protect Your Pallet Rack Uprights with Centurion

Pallet Rack Safety is essential for maintaining a secure and efficient warehouse environment. Optimized pallet racking provides a systematic way to store and manage palletized goods, maximizes vertical space, and facilitates easy access to products. Properly designed and installed pallet racking systems carry the following benefits:

-

- Promote efficient inventory management

- Streamline order fulfillment

- Ensure smooth warehouse operations

- Contribute to improved productivity

Pallet racking may seem simple; however, it’s part of the warehouse that can significantly impact a business’s bottom line, as it enables effective space utilization, reduces inventory handling costs, and minimizes product damage. This critical component of modern supply chain management can have even more impact when preventative measures are taken.

How Centurion Protects Pallet Rack Uprights

Centurion products protect the bottom of pallet rack uprights in the row and at the end. This does several things for the overall pallet rack safety:

Enhanced Stability

The bottom of the pallet rack uprights is susceptible to damage from forklift impacts, which can weaken the structural integrity of the entire racking system. Reinforcing the bottom of the uprights can increase the stability and durability of the rack uprights, reducing the risk of collapse or failure due to impacts or other stresses.

Prevention of Damage

Forklift impacts, accidental collisions, and other mishaps in the warehouse can cause damage to the bottom of pallet rack uprights over time. Reinforcing the bottom of the uprights can help prevent such damage.

Reasons to Choose Centurion During Pallet Racking Installation

Performing preventative measures, such as reinforcing rack uprights at the bottom and providing more rack stability on the ends of rows, is essential and cost-effective for several reasons when it comes to pallet racking installation in a warehouse:

1. Pallet Rack Safety

Warehouse racking systems are designed to hold heavy loads, and any damage or failure in the racking structure can result in serious accidents or injuries to workers. By reinforcing rack uprights at the bottom and providing additional stability at the ends of rows, you can prevent potential accidents caused by racking collapses, which can lead to injuries, damage to products, and costly lawsuits.

Pallet rack safety ensures employees feel secure in their workplace, which can lead to increased morale, higher job satisfaction, and better overall performance. Additionally, a safer work environment reduces the risk of accidents or injuries, resulting in lower workers’ compensation claims and insurance costs.

2. Cost savings

Repairing damages to pallet racking can be time-consuming and costly, as it may require taking the racking system offline, hiring specialized personnel, and ordering replacement parts. By implementing preventative measures, you can avoid or minimize the need for costly repairs or replacements in the future.

A business can allocate the budget that would have been spent on repairs or replacements to other critical areas, such as investing in technology upgrades, employee training, or improving other aspects of the warehouse infrastructure. These cost savings can contribute to improved profitability and competitiveness in the market.

3. Productivity

Racking failures or collapses can disrupt warehouse operations and result in downtime, leading to delays in order fulfillment and decreased productivity. By proactively reinforcing rack uprights and providing additional stability, you can ensure that your racking system remains reliable and functional, minimizing disruptions to your warehouse operations and maintaining high productivity levels.

Maintaining uninterrupted operations ensures that orders are processed, fulfilled, and shipped on time, which can positively impact customer satisfaction and retention.

4. Longevity of Pallet Racking Uprights and System

Pallet racking is a long-term investment for your warehouse, and taking preventive measures can extend the lifespan of your racking system by providing additional durability. By reinforcing rack uprights and providing stability, you can reduce the wear and tear on the racking system, preventing premature damage and extending its overall lifespan.

Pallet rack protection improves impact resistance, acting as a barrier and absorbing the impact of forklift, pallet, or equipment collision, reducing the risk of dents, cracks, or other damages that compromise structural integrity. Additionally, pallet racks protectors can reduce more frequent maintenance due to minimized occurrence of damages.

5. Compliance with Regulations

Many jurisdictions have safety regulations and pallet rackings safety guidelines, and failure to comply with these regulations can result in fines and penalties. By implementing preventative measures, you can ensure that your racking system meets or exceeds the safety requirements set forth by relevant regulations, keeping your warehouse compliant and avoiding potential legal consequences.

Compliance with regulations helps safeguard the business’s reputation as a responsible and reliable operation and avoids negative impacts on customer relationships.

Centurion Product Options for Pallet Rack Uprights

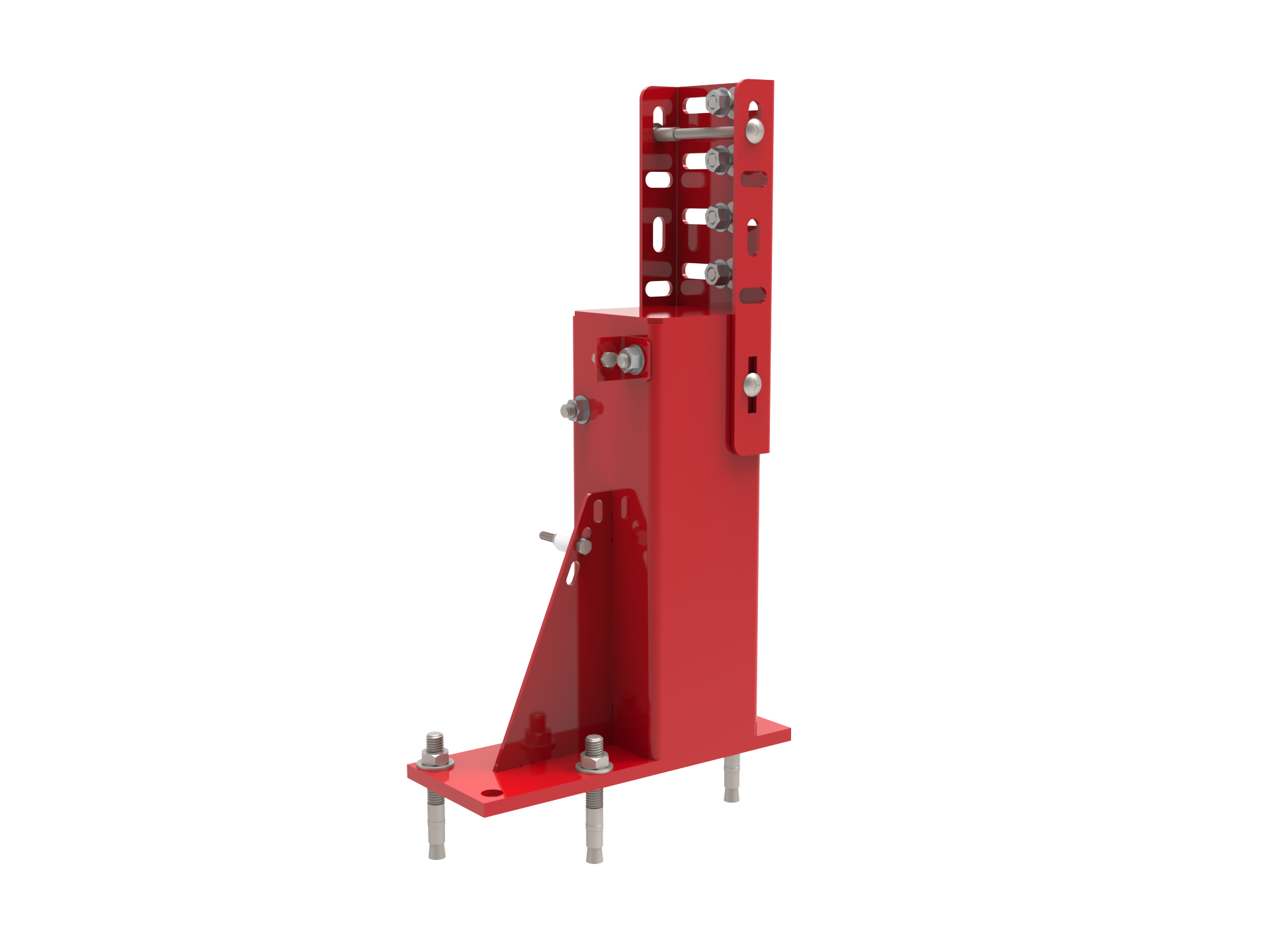

Centurion – Low Guard

The Centurion Low Guard is dedicated to the bottom 16” of the pallet rack upright and can be made to fit 3”, 4”, or 5” pallet rack uprights. The Low Guard is a cost-effective, heavy-duty solution to prevent damage to the bottom of the upright or at the base plate. The Low Guard includes wedge anchors, carriage bolts, ‘no snag’ side connections, a sturdy base, and a gusset for added strength.

Centurion – Row Guard

The Centurion Row Guard protects the end of the row of pallet rack uprights and is meant to replace the traditional industry-standard options. The Centurion Guard is custom fit to pallet racking and is available in a depth range of 36 to 48 and a height of 24 to 38. The Row Guard includes wedge anchors, carriage bolts, and a sturdy base.

In Conclusion

The many benefits of preventive pallet rack safety contribute to overall operational efficiency, profitability, and competitiveness in the market, allowing the business to focus on other critical areas of growth and success.

Even if preventative measures have not been taken for pallet rack damage, it is never too late to conduct a rack inspection and add pallet racking reinforcement. Rack inspections can help identify any existing damage, weaknesses, or potential safety hazards in the pallet racking system. Based on the inspection findings, appropriate measures can be taken to reinforce the damaged or weakened areas to ensure the stability and safety of the racking system.