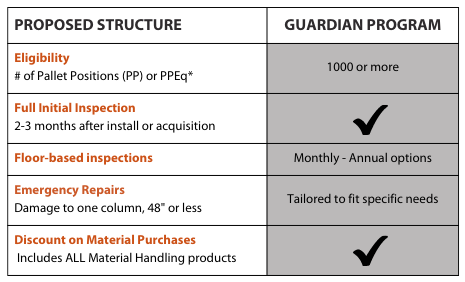

This subscription program provides you preventative and protective measures to help ensure the safe operation of the storage rack you’ve invested in. Below is an overview of the program, highlighting the main components and benefits along with the cost.

Initial Inspection

Completed by a team of professionals, this inspection is promptly followed up with a detailed report. All necessary lift equipment is included, and safety clips/pins are checked and added where missing.

Routine On-Site Inspections

Quarterly or semi-annual inspections from a certified rack professional to ensure that your racking systems remain safe and structurally sound.

Emergency Repairs

Damaged uprights will be repaired in less than 7 business days! Emergency repairs are included and apply to repairs where the upright damage is 48” or lower.

Discount on ALL Product Purchases

Yes, we mean all product purchases! This includes repair kits, replacement uprights, beams, warehouse protection, wire decks, and more. The discount even applies to custom solutions!

Initial Inspection

Completed by a team of professionals, this inspection is promptly followed up with a detailed report. All necessary lift equipment is included, and safety clips/pins are checked and added where missing.

Routine On-Site Inspections

Quarterly or semi-annual inspections from a certified rack professional to ensure that your racking systems remain safe and structurally sound.

Emergency Repairs

Damaged uprights will be repaired in less than 7 business days! Emergency repairs are included and apply to repairs where the upright damage is 48” or lower.

Discount on ALL Product Purchases

Yes, we mean all product purchases! This includes repair kits, replacement uprights, beams, warehouse protection, wire decks, and more. The discount even applies to custom solutions!

Program Details

*PPEq is the “Pallet Position Equivalent” for a system when traditional pallet positions are not used. This would equal the # of 48″D x 42″W x 48″H pallets that could fit safely on the upright and beam elevation, assuming the top pallet does not extend more than 24″ above the upright.

Components of a Pallet Rack Inspection

Visual Components Inspection

A visual inspection of the following components identifies damage, wear, or misalignment of racking systems.

Upright Frames – Inspected for proper alignment and visible damage of bending, twisting, or dents. Paint chips, corrosion, and rust are also examined as indicators of deeper structural weakness.

Bracing Supports – Inspected for damage or deformation, and missing or damaged bolts. Connections between bracing supports and upright frames are inspected for security.

Beams and Load Supports – Inspected for bending, deformities, or cracking. Security of connections is also checked by taking an inventory of all pins and clips and ensuring they are properly fastened.

Safety Accessories – Examination to be sure column protectors, aisle guards, and row spacers are installed adequately, intact, and not obstructing pathways.

Anchoring – The connection of pallet racks to the floor or base is inspected for evenness and damage, which may compromise rack stability. The floor is also inspected for evenness, cracks, or deterioration, as an indicator that the pallet racks installed on it are unsafe.

Load Distribution – Deflection and sagging of beams and shelves can indicate uneven weight distribution. Pallets are checked for proper position and that they themselves are not overloaded.

Labels – All pallet racks should be labeled according to capacity levels, safety warnings, and loading instructions. Inspections indicate that the labels are properly positioned and legible.

Load Capacity Evaluation

Dynamic vs. Static Loads – Determination of the capacity in relation to manufacturer’s specifications of maximum weight based on whether the pallet loads are stationary or subject to handling and movement.

Uniformly Distributed Load – Determination if the weight of pallets is evenly distributed along the shelves to avoid concentrated weights that may compromise the racking system.

Rack Configuration – Varying types of racking systems have different load capacities per their structural characteristics. Examination of adherence to manufacturer specifications.

Spacing of Rack Beams – Manufacturer’s specifications of load capacity indicate maximum allowable load weights related to the spacing of the beams. Examination of adherence to manufacturer specifications.

Safety – Maintaining a margin below the manufacturer’s specification is a common safety factor. Examination of load weight in relation to the specifications.

Rack Guardian Program Enrollment

"*" indicates required fields

Reviews

“Great design of this rack repair kit. I enjoyed the simple install of these units. Cutting out approx. 30 lbs. of damaged steel and replacing it with approx. 110 lbs. of strong steel bracing, with heavy duty 3/4″ diameter wedge floor anchors.”

“Overall, we estimate around a 93% cost reduction by using [pallet rack repair] kits. This is a great product. I am really surprised more warehouses and factories are not utilizing this solution.”

Site by tiny blue orange.